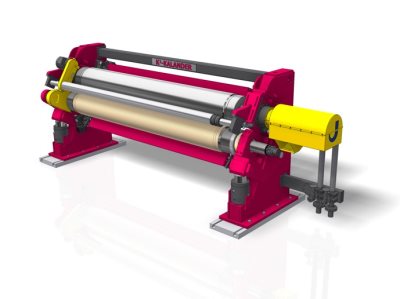

Calenders are used in order to change the surface properties of uncoated paper or coated qualities or to manufacture paper with a certain density. The paper industry distinguishes between a series of calenders: 2-roller calenders, multi-roller calenders, super calenders for glazing, or highly heated multinip calender systems, which work both outside the paper machine (“offline”) and are also integrated in paper machines (“online”). Conversions in paper quality mean that calendering processes repeatedly have to be adjusted. Before costly new installations are necessary in these cases, the existing systems can be adapted with the corresponding expertise and finely adjusted to the new tasks.

Jagenberg Paper Systems has an experienced team of machine specialists on board here who not only provide you with advice, but are also available for the implementation. It is clear that calenders also age, especially when they are used in continuous operation. Mechanical overhauls become necessary, automatic control systems require updates or the safety technology has to be checked and brought up to date. We call this process retrofitting and we enjoy a reputation in the industry of being particularly well suited for the task. “Relocating” a calender system that is offline to another application location or another production location is also part of our service portfolio.